While the world struggles to end greenhouse gas pollution, a handful of innovators are developing ways to clean it up. Their efforts could reverse climate change.

The atmosphere is a true marvel of engineering – a gaseous cocoon that makes life possible on earth. Nitrogen, oxygen and ozone prevent dangerous, high frequency cosmic radiation from reaching the earth’s surface. At the same time, the atmosphere allows visible, life-giving frequencies of sunlight to pass through a kind of window (illustration below).

The atmosphere also maintains temperatures ideal for life. Carbon dioxide, water vapor and methane absorb and disperse the heat radiating from the earth’s surface. This produces the so-called “greenhouse effect”. Without these naturally occurring heat trapping gases, average global temperatures would be about 30 °C colder.

Increasingly, the greenhouse gases (GHGs) produced by human activity are amplifying the heat-trapping properties of the atmosphere, with the now-familiar apocalyptic symptoms: frequent extreme storms, widespread severe drought, wildfire of unprecedented scale, rapidly melting glaciation, and rising sea levels.

The cause and effect of greenhouse gas pollution has become so obvious that the climate crisis can now be summarized in stark terms: Greenhouse gas pollution is dangerously warming the atmosphere. The appropriate response now seems equally obvious: Stop greenhouse gas pollution. Clean it up.

Ways and means

Until recently, the international response to climate change has focused on stopping GHG pollution. Those efforts continue to move along three basic pathways: replacing machinery that burns fossil fuels with devices that run on electricity or zero carbon energy such as wind, solar and geothermal; discontinuing the use of certain industrial chemicals containing fluorine; and reforming land use practices. This has proven to be a complex international undertaking. System change and countless individual actions are required within these spheres of economic activity. Getting all the players in the affected sectors to cooperate in the context of a competitive, bottom-line-oriented world economy is time-consuming. We are likely decades away from a carbon-neutral world if stopping pollution remains the primary goal.

So zero carbon strategies are broadening to include the cleanup of an estimated 1.5 trillion tonnes of carbon dioxide that have accumulated in the atmosphere since the industrial revolution. Compared to eliminating a multitude of GHG sources worldwide, cleanup scenarios are, practically speaking, simple and straightforward: remove carbon dioxide from the atmosphere, permanently and safely store it, and use some of the CO2 or its derivatives as a valuable industrial material. The politics are simpler too. Removing pollution does not require international cooperation. It has zero disruptive effect on the economic status quo. It’s a wide-open field with no industrial incumbents needing to be replaced or shut down. A handful of technologies deployed globally by well-funded public or private organizations could do the job.

Carbon dioxide pollution accounts for about 75 percent of global greenhouse gas emissions. It is also the only greenhouse gas for which there are proven methods of removal. These methods are categorized by the Intergovernmental Panel on Climate Change as “negative emissions”, or carbon dioxide removal (CDR). Distinct from removing CO2 from the flue gas of an industrial plant, CDR removes carbon dioxide directly from the atmosphere. This can be achieved by direct air capture (DAC) technologies and by the enhancement of natural carbon sinks such as soils and surface geology. The captured CO2 can be stored in geological formations, sold to fizzy drink makers, or broken down into oxygen gas and solid carbon, a valuable industrial material.

Carbon dioxide removal is a pragmatic and perhaps overdue shift in climate change thinking and strategy. In an article published in Issues in Science and Technology, Dr. Klaus Lackner and Christophe Jospe re-frame climate change as a waste management problem. “Carbon dioxide emissions represent the metabolic by-product of industrial activities on which billions of people depend to survive and thrive. Now we must learn to safely dispose of this by-product,” they write. While Lackner and Jospe stop short of calling CDR a panacea, they do identify its key role in eliminating greenhouse gas pollution.

“Direct air capture will not be a silver bullet that all by itself stops climate change, but it has many assets that can directly address some of the key obstacles to technical, political, and economic progress on climate change,” they write. The scalability and relative simplicity of DAC could ensure that “whatever goes into the atmosphere also comes out, no matter how difficult it is to reduce emissions from particular technologies or sectors, such as transportation. Direct air capture with carbon storage can also, if necessary, lower the carbon dioxide concentration in the atmosphere much faster than natural processes would.”

Klaus Lackner is the director of the Center for Negative Carbon Emissions at Arizona State University and a pioneer in developing DAC since the mid 1990s. His co-author, Christophe Jospe, is Chief Development Officer at Nori, a Seattle-based company that focuses on carbon storage and usage. Nori treats CO2 as a raw material and connects CO2 suppliers with CO2 buyers. Storing carbon dioxide will entail significant cost, so treating it as a raw material is crucial. In other words, valuable products, derived from captured CO2, could finance a good part of a global cleanup operation.

Diverse pathways, a single purpose

A number of forward-looking organizations, with financial support from government and private investors, are making carbon dioxide removal a reality using DAC and enhanced mineralization processes. They are using CO2 to make stronger concrete, or using it as a feed stock for ultra strong carbon materials. They are combining CO2 with hydrogen to make synthetic fuel, or sequestering the gas permanently underground.

Silicon Kingdom Holdings, (SKH) based in Dublin, Ireland, is planning to build mechanical tree farms using the capture technology developed by Dr. Lackner. Thousands of times more efficient than natural trees, the devices use anion exchange membranes to remove CO2 from ambient air. A sodium carbonate solution and heat further separate and purify the gas. The CO2 is then pressurized and made available for sequestration or for use in a variety of industrial applications such as synthetic fuels and high strength materials. SKH was established by a group of business and science innovators, including Dr. Lackner, in association with Arizona State University.

Carbon Engineering, based in Squamish, Canada, has designed modular devices that blow ambient air over a capture solution. A closed loop series of chemical processes fixes CO2 and releases it in concentrated form. The firm plans to build full-scale DAC plants to capture a million tonnes of CO2 annually at about $US100 a tonne. The CO2 will be permanently stored underground or combined with hydrogen to make synthetic transportation fuel. Carbon Engineering recently received a $25 million repayable investment from the Government of Canada’s Strategic Innovation Fund and has secured over CA$100 million from private investors including Murray Edwards and Bill Gates. The firm is partnering with 1PointFive in the US and Pale Blue Dot in the UK to finance and build commercial DAC plants.

Climeworks of Switzerland is operating a demonstration plant near Zurich that can remove 900 metric tonnes of CO2 from the atmosphere yearly. Similar to Carbon Engineering’s technology, fans blow CO2 through modular units roughly the size of shipping containers. Filters in the units capture the gas, then release it for collection. A small demonstration plant in Troia, Italy, will collect 150 tonnes of CO2 per year. Similar to Carbon Engineering’s process, the CO2 is combined with hydrogen to produce synthetic fuel.

Climeworks also permanently sequesters carbon dioxide underground. In 2019, the organization introduced a public removal and sequestration scheme in partnership with Reykjavik Energy of Iceland. Through its subsidiary CarbFix, Reykjavik Energy injects CO2 from a 303 MW geothermal power plant into subsurface basalt rock. The injected CO2 mineralizes into solid carbonate rock in less than two years. The Climeworks website invites individuals and organizations to pay a monthly subscription – in amounts up to €2,000 per month – to help fund the project. For example, €5 per month will sponsor the sequestration of 61 kilograms of CO2 yearly.

Globally, the storage capacity of basalt is immense. The rock composes about 10 percent of the earth’s continental surface area and underlies most of the planet’s ocean floor. The potential mineral uptake of basalt formations is estimated at between 100 and 250 trillion tons – in theory enough to absorb all the excess CO2 in the atmosphere a hundred times over.

In Halifax, Canada, CarbonCure injects recycled CO2 into cement during the mixing process. The CO2 mineralizes into calcium carbonate and actually strengthens the concrete as it cures. The process permanently fixes CO2 at relatively low cost, and if scaled to the global concrete market, could sequester over 500 megatons of CO2 annually. CarbonCure presently obtains its CO2 from established suppliers such as fertilizer plants and other cement producers. It expects to use CO2 from DAC technologies as they become available. Breakthrough Energy Ventures, established by Bill Gates and a coalition of private investors including Jeff Bezos and Richard Branson, have invested in the company.

In San Francisco, USA, Charm Industrial has a patent pending for a process that produces bio-oil for storage deep underground. Fast pyrolysis converts the carbohydrate compounds in scrap wood, sawdust, and agricultural waste into a stable liquid similar to crude oil. In effect, the company is reversing crude oil extraction and returning carbon to its geological source.

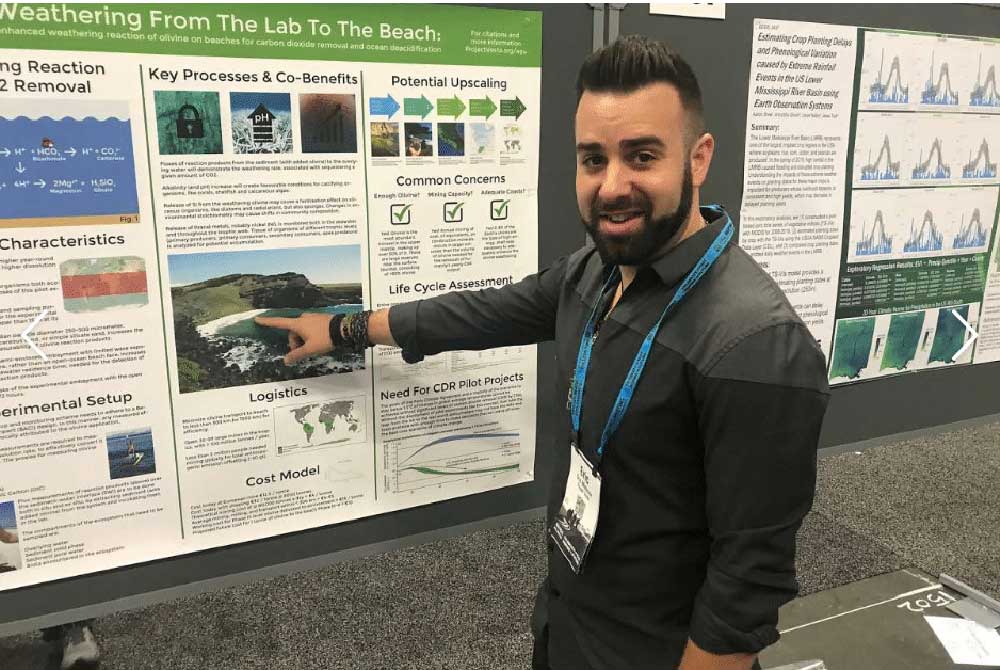

Also in San Francisco, Project Vesta, a non-profit venture, captures CO2 by accelerating the natural weathering of rock. Small grains of olivine, an abundant green volcanic mineral, are spread like sand on shallow beach environments. Wave action abrades the olivine, increasing its surface area. In the process, the mineral reacts to atmospheric CO2 and ocean water – the same silicate-to-carbonate chemical reaction as natural weathering. The olivine becomes limestone which collects on the seafloor. Research suggest that applying olivine on just 2 percent of the world’s shallow ocean shelves would remove one year’s worth of annual global CO2 emissions at low cost. A pilot project is underway on a Caribbean beach, but more testing is required to answer questions about safety and viability.

Stripe, the payment software company, has given financial support to Project Vesta, Charm Industrial, Climeworks and Carboncure. Instead of spending money on projects that curtail emissions through carbon offset programs, the company is distributing US$ 1 million among these four ventures to help remove carbon dioxide from the air.

Meanwhile, C2CNT, comprised of a team of researchers and engineers led by Dr. Stuart Licht of George Washington University, is running a demonstration project at a coal-fired electricity generation plant near Edmonton, Canada. The project captures CO2 from flue gas to produce carbon nanotubes. Using electrolysis, the CO2 is split into oxygen and carbon fibres. The fibres can take different forms for different applications. One form, carbon nanotubes, are a hi-tech industrial material used to make aircraft bodies, tennis rackets and other strong lightweight products. The highest quality nanotubes produced by conventional methods can fetch up to $100,000 per kilogram. Another form of carbon, graphene, is suitable for safe, stable sequestration. The C2CNT project is one of 10 finalists in the Carbon Xprize competition awarded US$500,000 to demonstrate technologies that convert CO2 into valuable products. Capital Power, the owner of the generation plant and host of the demonstration project has invested in C2CNT with the aim of removing CO2 from their flue gas.

A DAC version of the technology would be self-powered using solar thermal and photovoltaic energy. According to Licht’s calculations, full scale deployment in an area about 10 percent the size of the Sahara Desert could reduce atmospheric CO2 concentrations to pre-industrial levels in as little as 10 years.

Technical innovation goes through several stages. Often, it will start in a university lab. It will then attract the interest of private investors. When things begin to take shape, governments will provide grants. There will be a demonstration phase followed by the technology’s entrance into mainstream markets. Once adopted by the marketplace, costs can go down with economies of scale and the development of production efficiencies. The development of DAC has taken that path. The C2CNT project started in a lab at George Washington University and is now working out of the Genesee generating station, near Edmonton, Canada. When Climeworks’ technology became commercially available in 2014, it captured carbon dioxide for about US$600 per tonne. It now expects to bring costs down closer to US$100 per tonne in two or three years. Carbon Engineering appears to have beaten them to the punch. In 2019 it announced that its fully demonstrated DAC technology was capable of capturing and purifying atmospheric carbon dioxide for under US$100 per tonne.

With CDR, investors like Bill Gates may realize that the near-term cost of cleaning up carbon dioxide pollution is the most pragmatic way to avoid the even costlier long-term effects of the pollution. Capital power, meanwhile, has invested in the C2CNT project in order to continue burning coal to generate electricity. It aims to stop CO2 emissions and pay for the cost of doing so by selling high-value carbon nanotubes derived from those emissions.

As we confront the deepening climate crisis, it helps to remember that we are facing a greenhouse gas pollution crisis, or perhaps less dramatically, a waste management challenge. As we meet that challenge by stopping the pollution at source and removing anthropogenic carbon dioxide from the atmosphere, we can expect things to cool down.